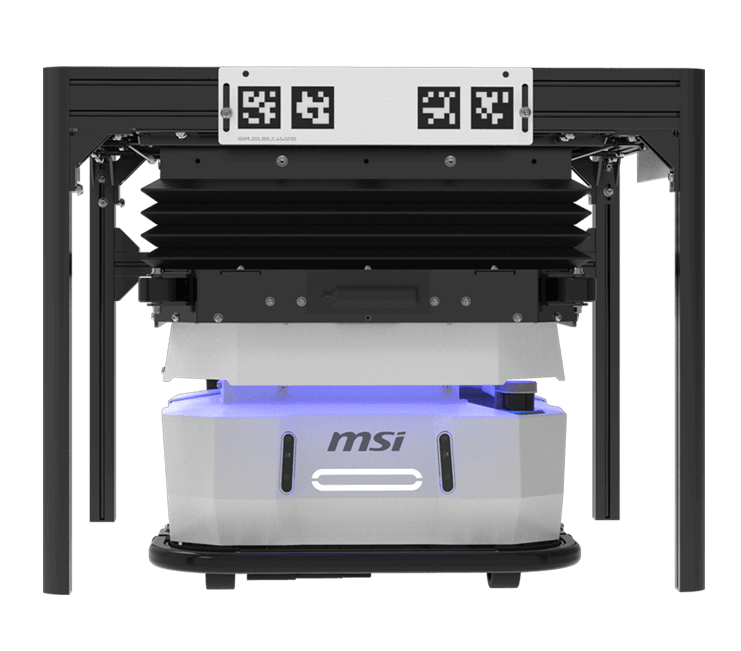

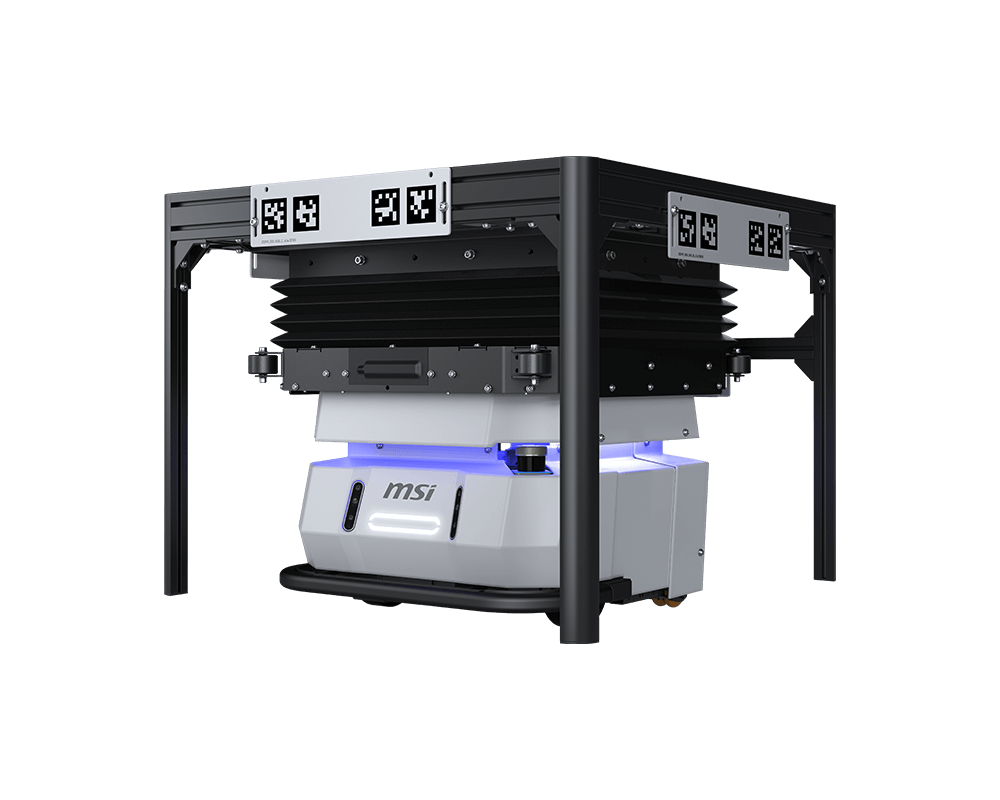

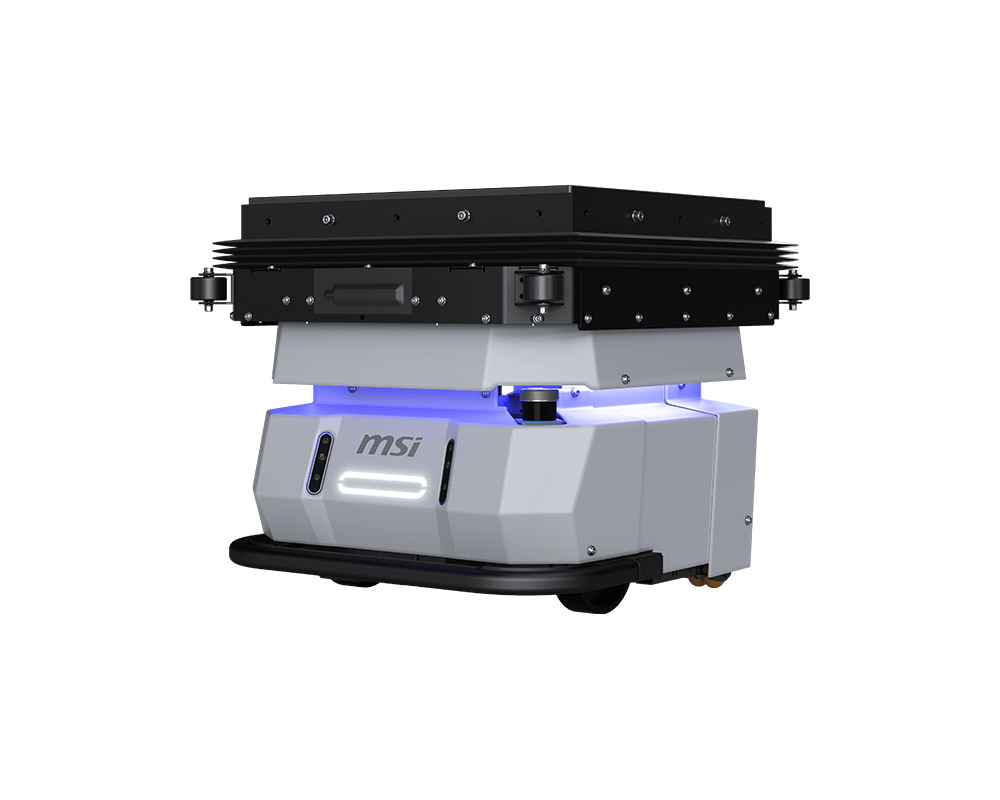

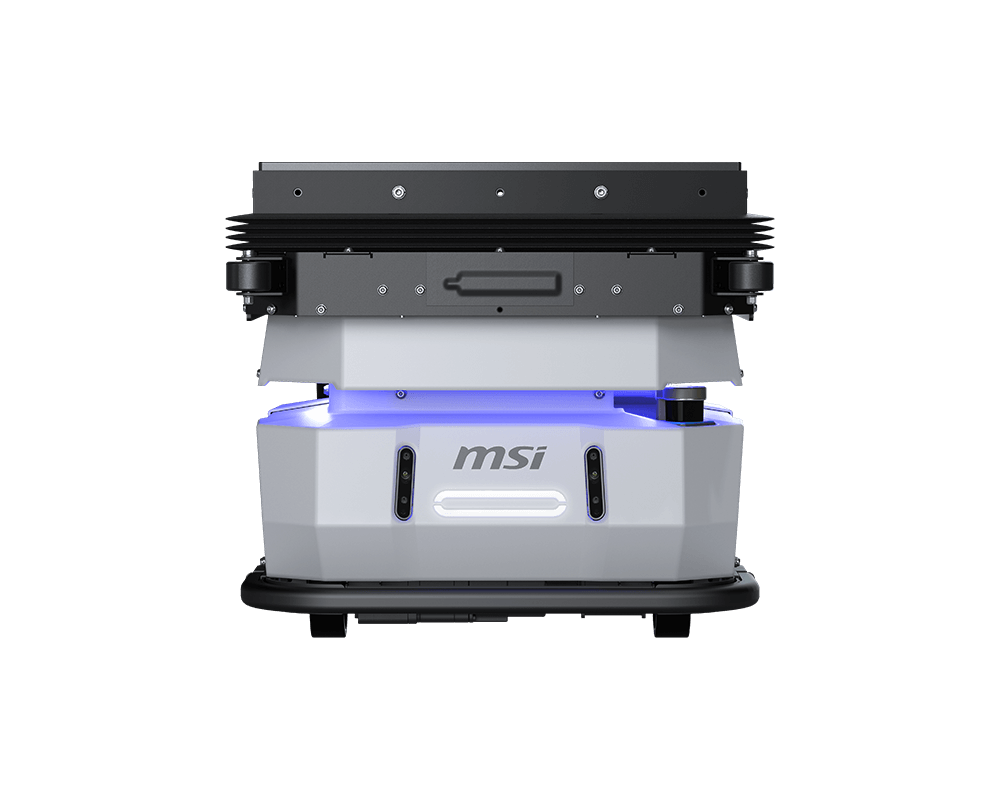

AMR-AI-Lift Robot

Intelligent recognition technology, fast and secure operation, flexible application, efficiency at its best!

Intelligent Shelf Recognition Management

Equipped with advanced identification technology, capable of automatically recognizing shelf codes and operating various shelves. Through smart algorithms, robots can accurately extract and place goods, ensuring efficient and error-free material handling and management.

Diversified Shelf Compatibility

Can easily adapt to various standard shelves and custom shelves, and has a strong load-bearing capacity, able to withstand up to 150kg of goods weight, ensuring flexible application in different warehouses or production environments without the need for large-scale equipment modification.

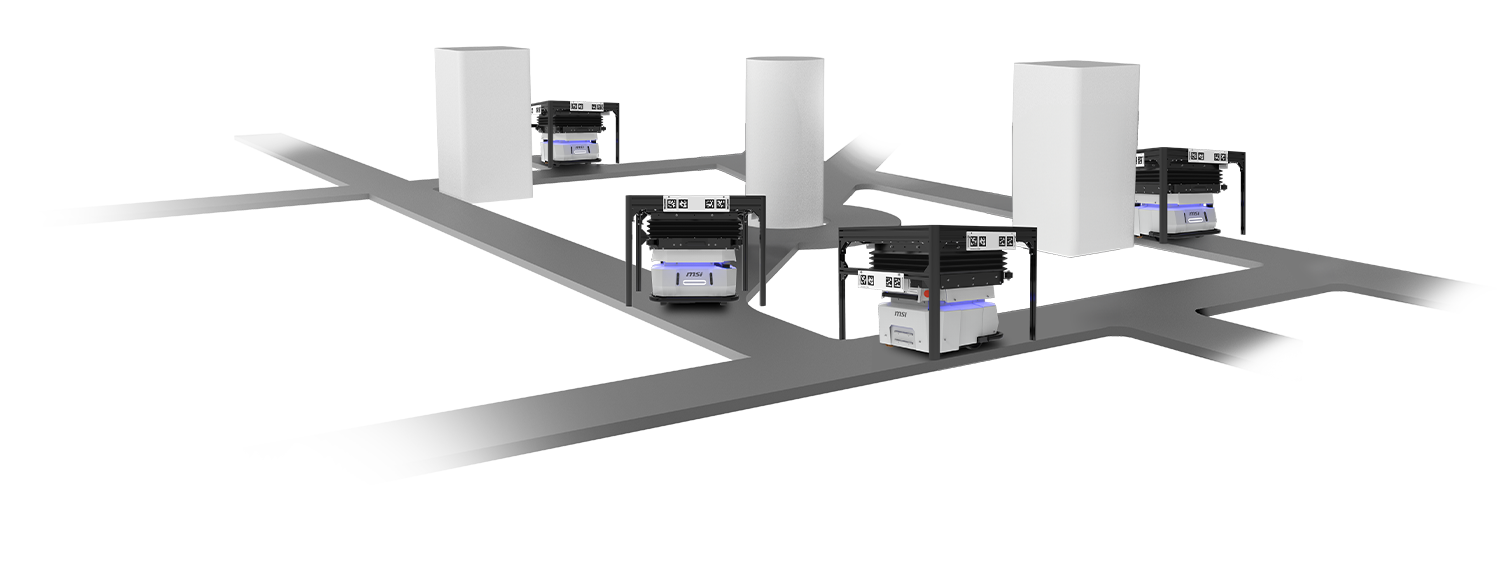

Efficient Collaborative Work

Intelligent lifting robots can achieve multi-machine cooperation, optimize the overall carrying capacity, work in coordination with each other, and operate in an orderly manner. Their efficient collaborative working capability significantly enhances the overall operational efficiency of storage and production lines.

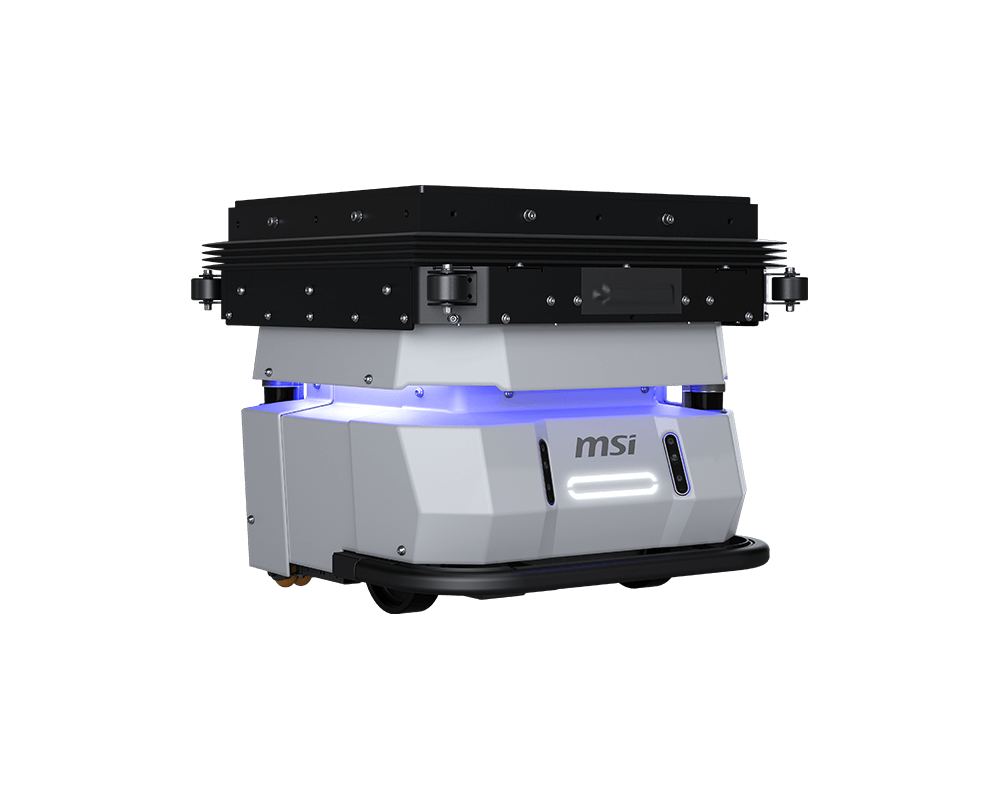

Technical Specifications

Product dimension

Length/ Width/ Depth

L: 705 x W: 620 x H: 561 (mm)

Weight

135kg

Performance

Extra affordable payload

150kg

Run time

8 hours

Run speed

Max 1.3m / sec

Precisions

± 50mm

Minimum run width

1005mm

Traversable gap

5mm

Climb grade

7°

Sensors/Security

Lidar

Front x1 , Rear x1

3D Camera

Intel® RealSense™ X3

Security

Emergency Stop Button

Contact

Standard configuration

Wireless 802.11 a/b/g/n/ac

Optional

5G

Power

Battery

48V/33.6Ah

Charger time

≤ 2 hours

Charger device

Dock Charger: 30A

Environment

Related specifications

CE, Semi S2

Application specific modules

Network

RJ45 X1

USB

USB x2

Power

48V/23.5A(Battery Power)

Modbus protocol

Optional

AMR-AI-Lift Robot

- High-Speed Operation: Fast transportation to enhance work efficiency.

- Safety Anti-Collision System: Equipped with environmental recognition and anti-collision features.

- Laser Scanning and 3D Obstacle Avoidance: Ensures safety in changing environments.

- Autonomous Movement: Adapts to a variety of work scenarios.

- Diverse Load Options: Choose the appropriate shelf load specifications based on requirements.

- Autonomous Charging: Achieves long hours of continuous work.

- Flexible Application: Suitable for various fields including mechanical processing industry, electronic manufacturing, and warehousing logistics.