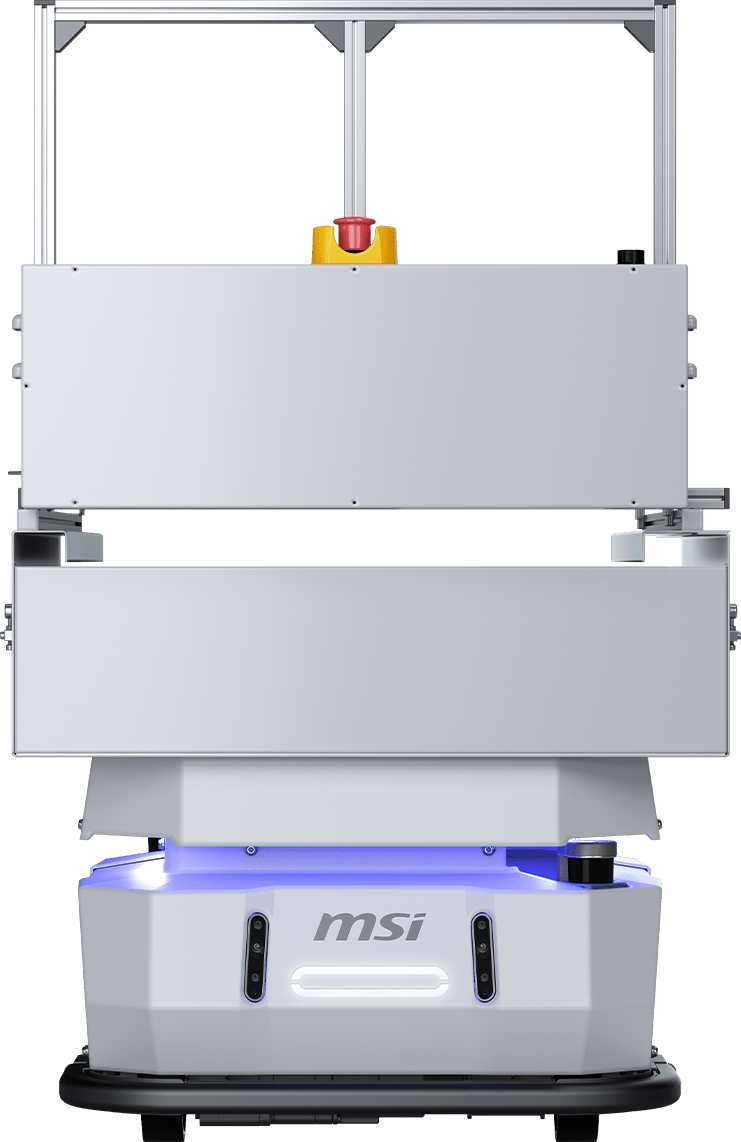

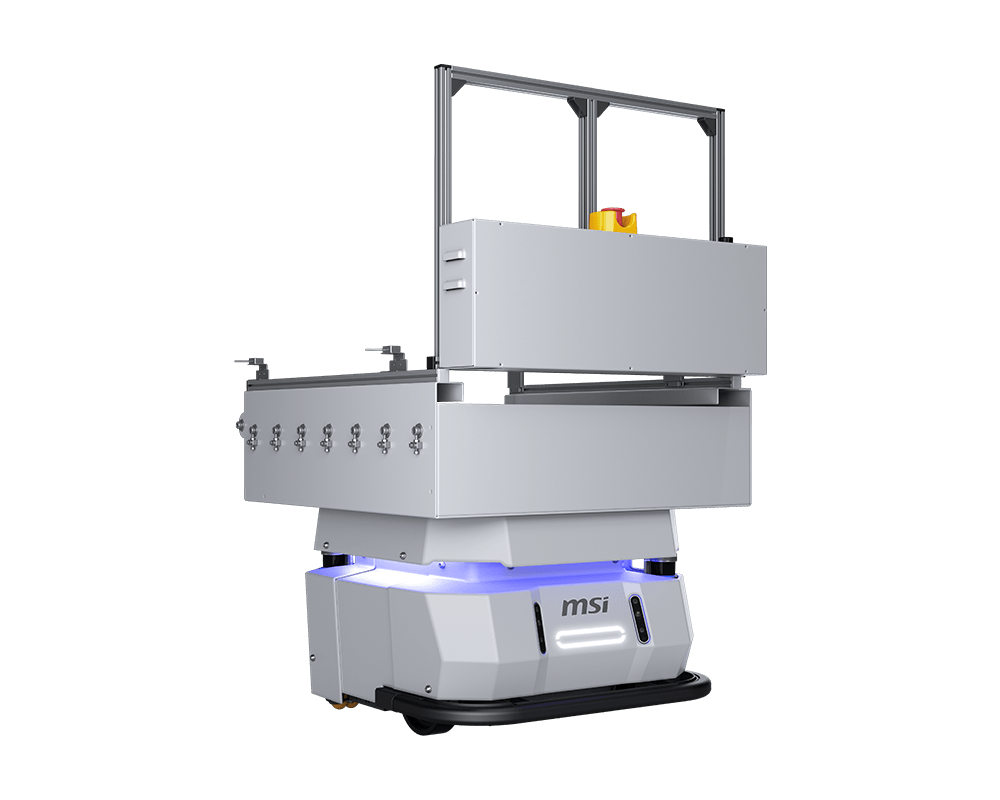

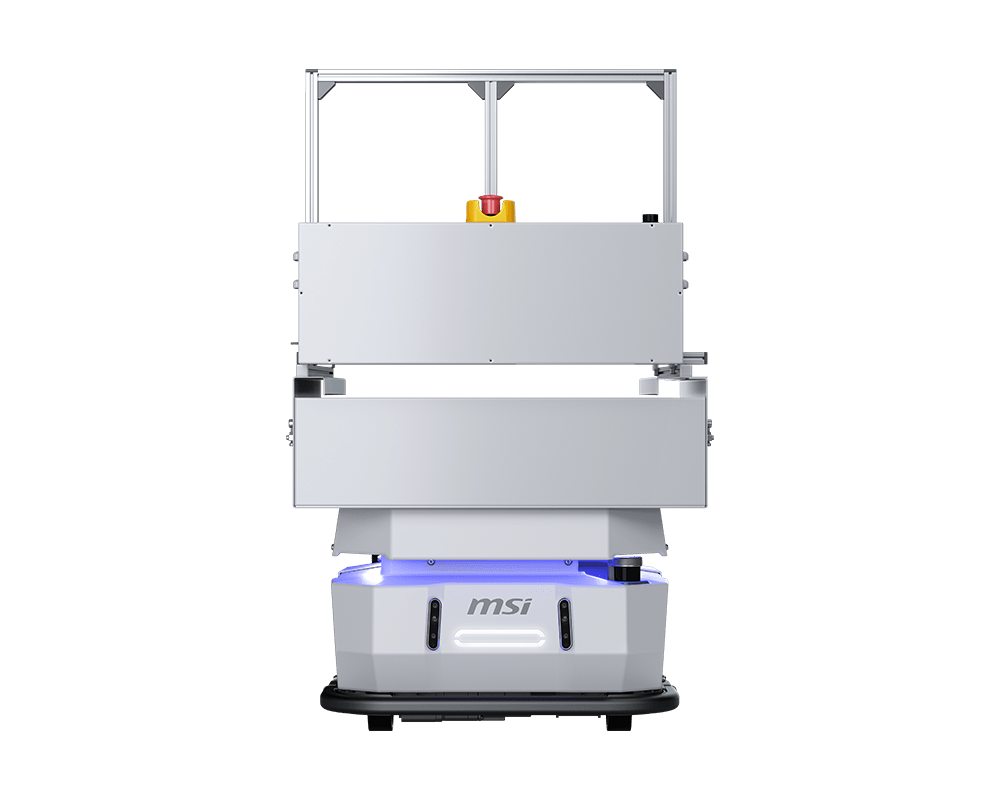

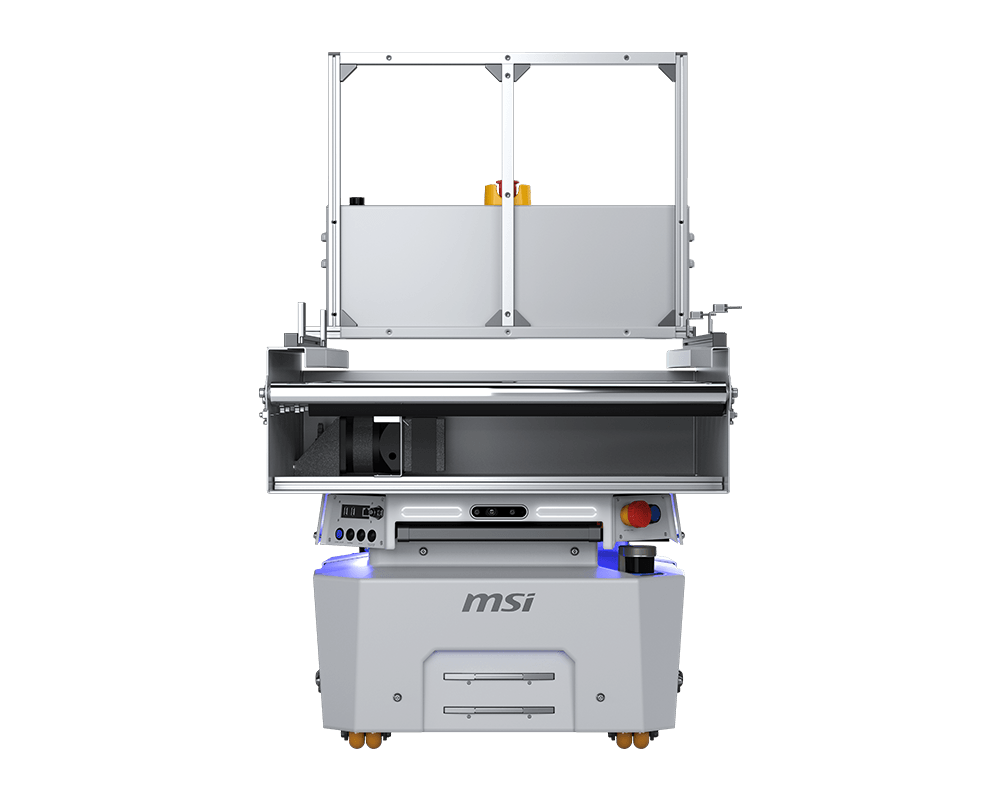

AMR-AI-Roller Robot

Perfect integration, flexible management, efficient collaboration, intelligent communication, comprehensively enhancing production efficiency!

Equipment Scheduling,

Easy Switching

When the production line needs to change configurations, the roller robots can seamlessly dock with various production line equipment without the need for large-scale equipment adjustments, and are equipped with automatic identification and docking functions, capable of working efficiently in collaboration with different automation systems, enhancing the overall operational efficiency.

Smart Factory, Communication Without Barriers

Equipped with advanced autonomous communication capabilities, it can seamlessly interface with production line equipment. Utilizing wireless data transmission technology, it ensures fast and stable data transfer, enhances the degree of automation and overall operational efficiency, and reduces the risk of manual intervention and errors.

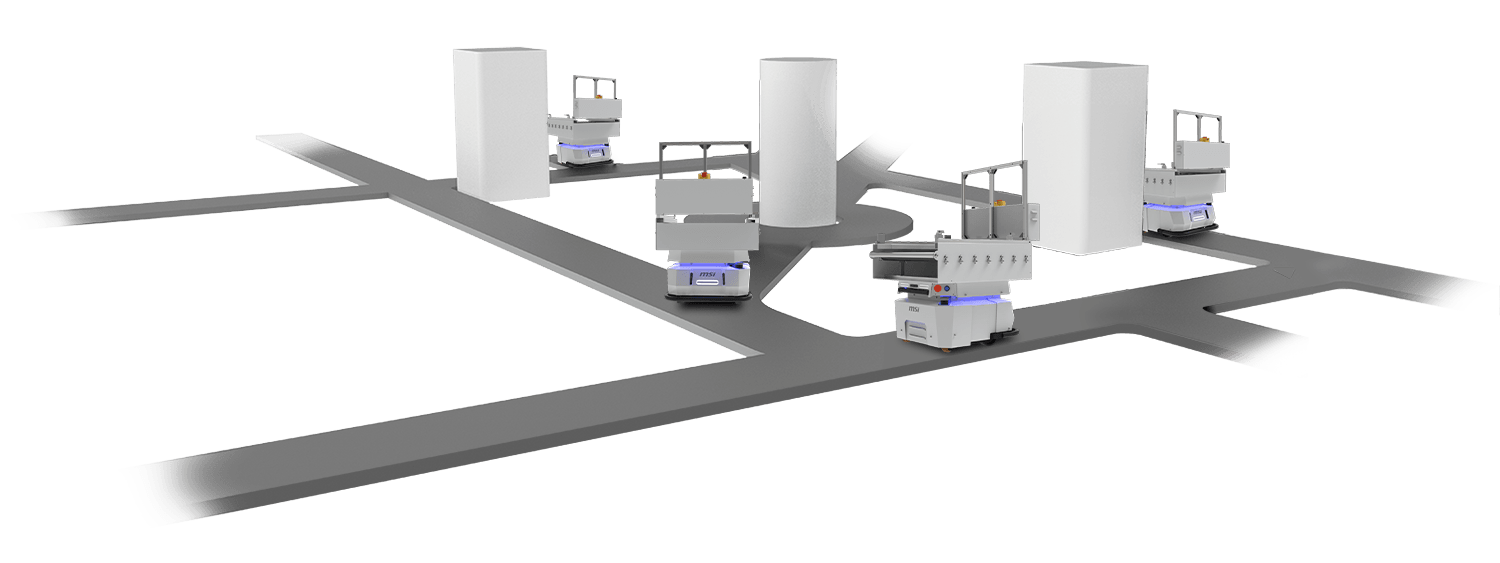

Multi-Machine Cooperation, Efficient Collaboration

Intelligent roller robots can achieve multi-machine cooperation, optimize the overall carrying capacity, work in coordination with each other, and operate in an orderly manner. Their efficient collaborative working capability significantly enhances the overall operational efficiency of storage and production lines.

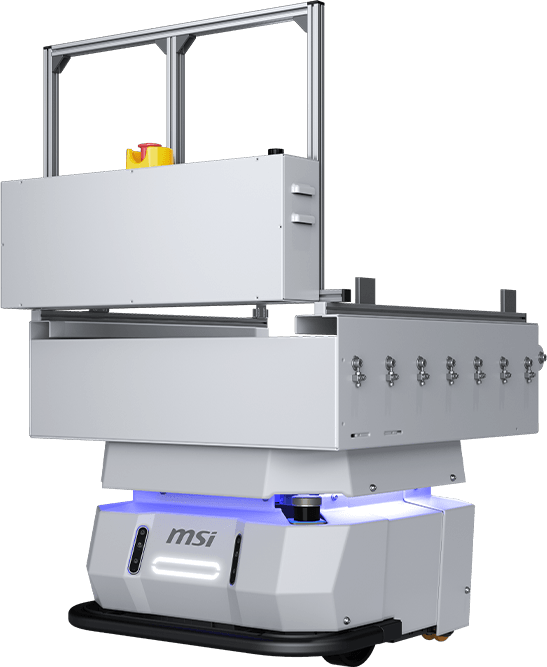

Technical Specifications

Product Dimension

Length/ Width/ Depth

L: 811 x W: 674 x H: 1101 (mm)

Weight

145kg

Performance

Extra Affordable Payload

150kg

Run time

8 hours

Run speed

Max 1.3m / sec

Precisions

± 50mm

Minimum run width

1005mm

Traversable gap

5mm

Climb grade

7°

Sensors/Security

Lidar

Front x1 , Rear x1

3D Camera

Intel® RealSense™ X3

Security

Emergency Stop Button

Contact

Standard configuration

Wireless 802.11 a/b/g/n/ac

Optional

5G

Power

Battery

48V/33.6Ah

Charger time

≤ 2 hours

Charger device

Dock Charger: 30A

Environment

Related specifications

CE, Semi S2

Application Specific Modules

Network

RJ45 X1

USB

USB x2

Power

48V/23.5A(Battery Power)

Modbus protocol

Optional

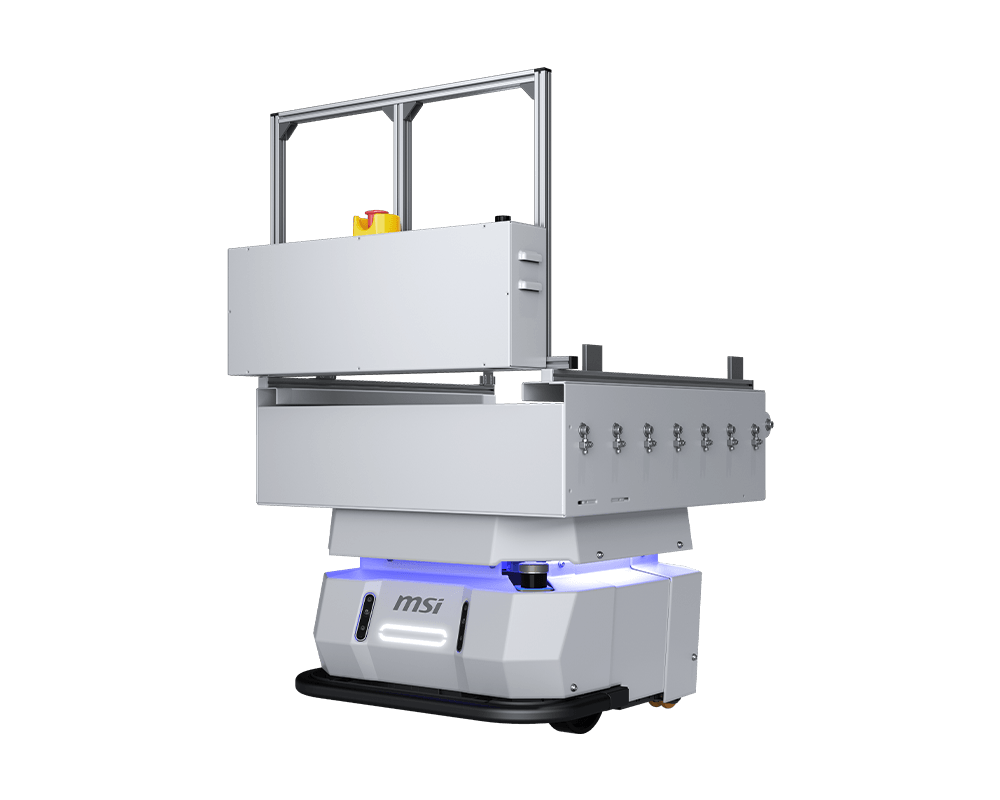

AMR-AI-Roller Robot

- Autonomous Navigation: Utilizes advanced technologies such as inertial navigation and visual navigation for precise positioning.

- Trajectory Management: Effectively controls the operational path.

- Flexible Operation: Roller conveyance saves manual handling and increases productivity.

- Autonomous Charging: Enables long periods of continuous operation.

- Safety Anti-Collision System: Equipped with environmental recognition and anti-collision capabilities.

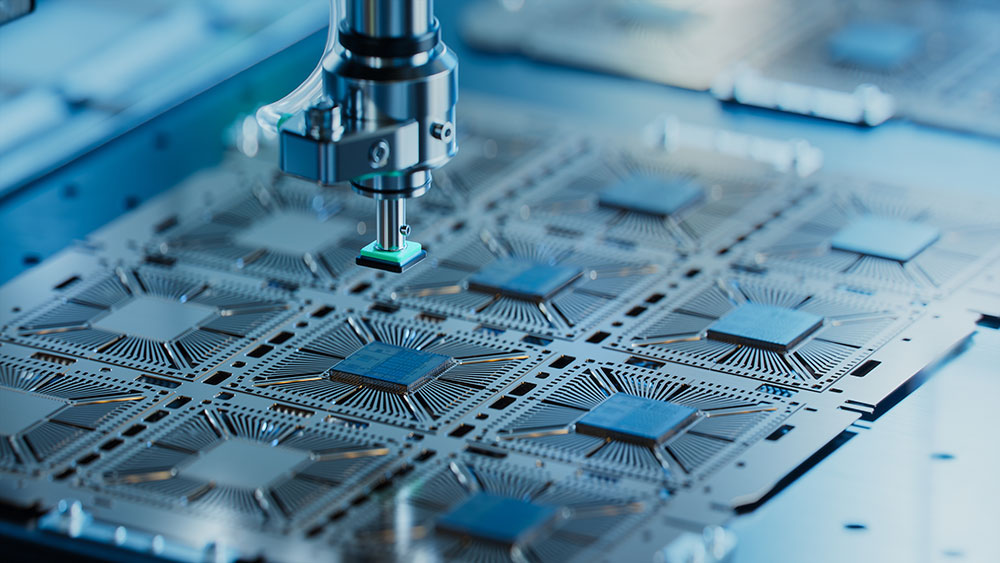

- Flexible Application: Suitable for various fields including food industry, electronic manufacturing, and warehousing logistics.